UYO STADIUM

- Client: Bilfinger Berger AG Nigeria Division & Julius Berger Nigeria PLC / Akwa Ibom State Government

- Location: Uyo, Nigeria

- Project status: Completed 2014

Project characteristics:

MEP – Mechanical, Plumbing & Electrical Works, Procurement and Delivery (FOS Uyo), Installation, Testing and Commissioning.

Buildings: Main Stadium incl. Ticket Booth, Infrastructure, Generator House, Sewage Treatment Plant, Water Reservoir, Workshop, Diesel Gen sets / Switchgear, Gate House I & II, Training Pitch (~ 64,700 m2).

Sanitary and Fire Protection: Sewerage System, Storm Water Drainage, Water Supply – Hot & Cold, FF Extinguisher.

Mechanical: Diesel Oil Supply System.

ELV Systems: PABX, Public Address, Clock System, Audio-Video System, Multimedia, CATV, Fire alarm, CCTV.

Electrical LV: 3xGen-Sets 1500kVA + 1xGen-Sets 800kVA, UPS, Power supply cables and SDBs, Internal lighting system, Sports lighting, Decorative Luminaries, Dimming system, Earthing & Lightning.

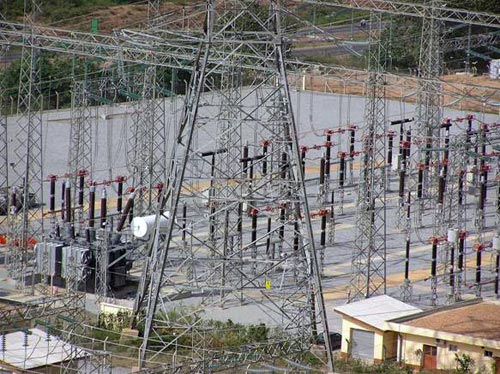

Electrical Infrastructure: 4x11kV substations (switchgear and transformers), 4 x Main switchgear (MDB) 0,415kV, Street lighting, Decorative luminaries, Fire Alarm, CCTV cabling, Fiber optic cabling.

HVAC & Control System: CHW System with Fresh Air Supply, DX Units System, Ventilation, MCC.

Plumbing Infrastructure: Fire Fighting System, Irrigation System and Potable Water Supply System, WTP, Pump Stations – Fire Fighting & Potable & Irrigation, STP.